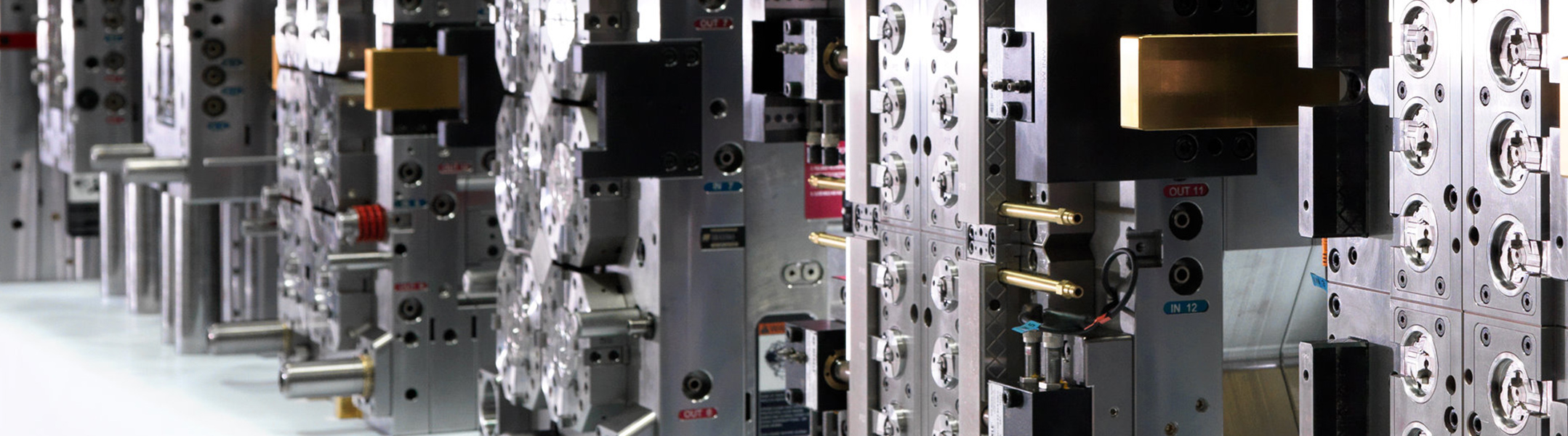

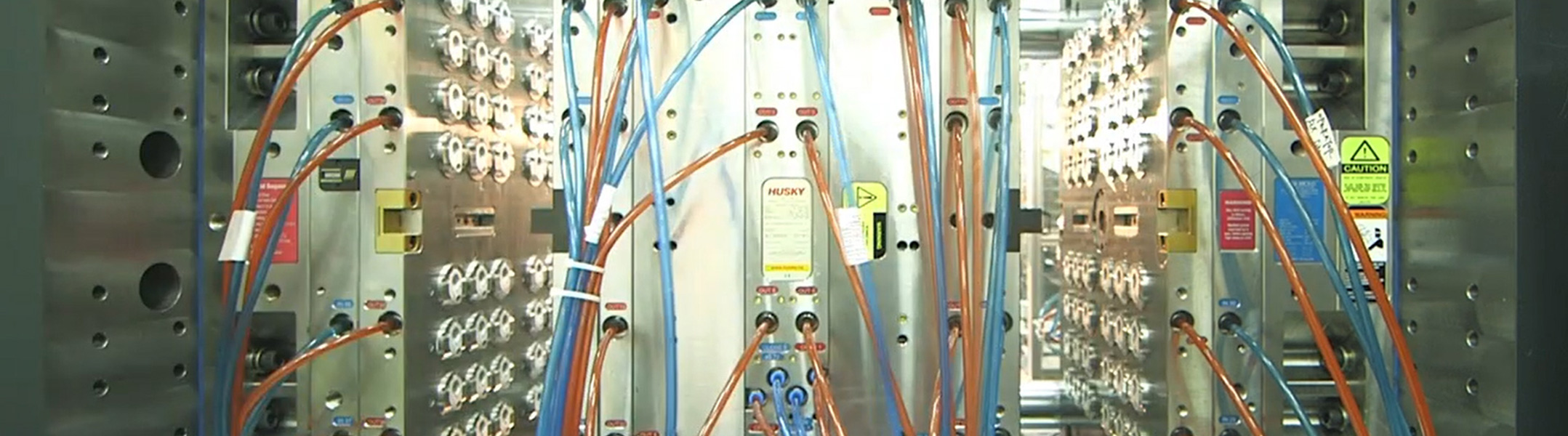

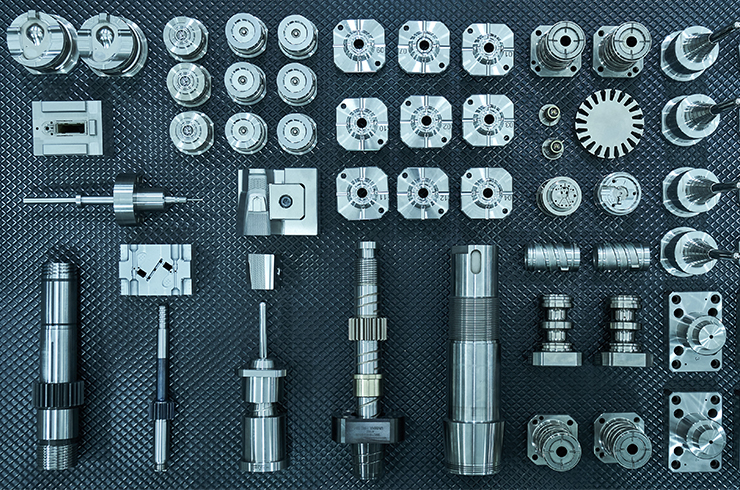

One Of The Most Advanced Ultra Precision Mould Making Operations

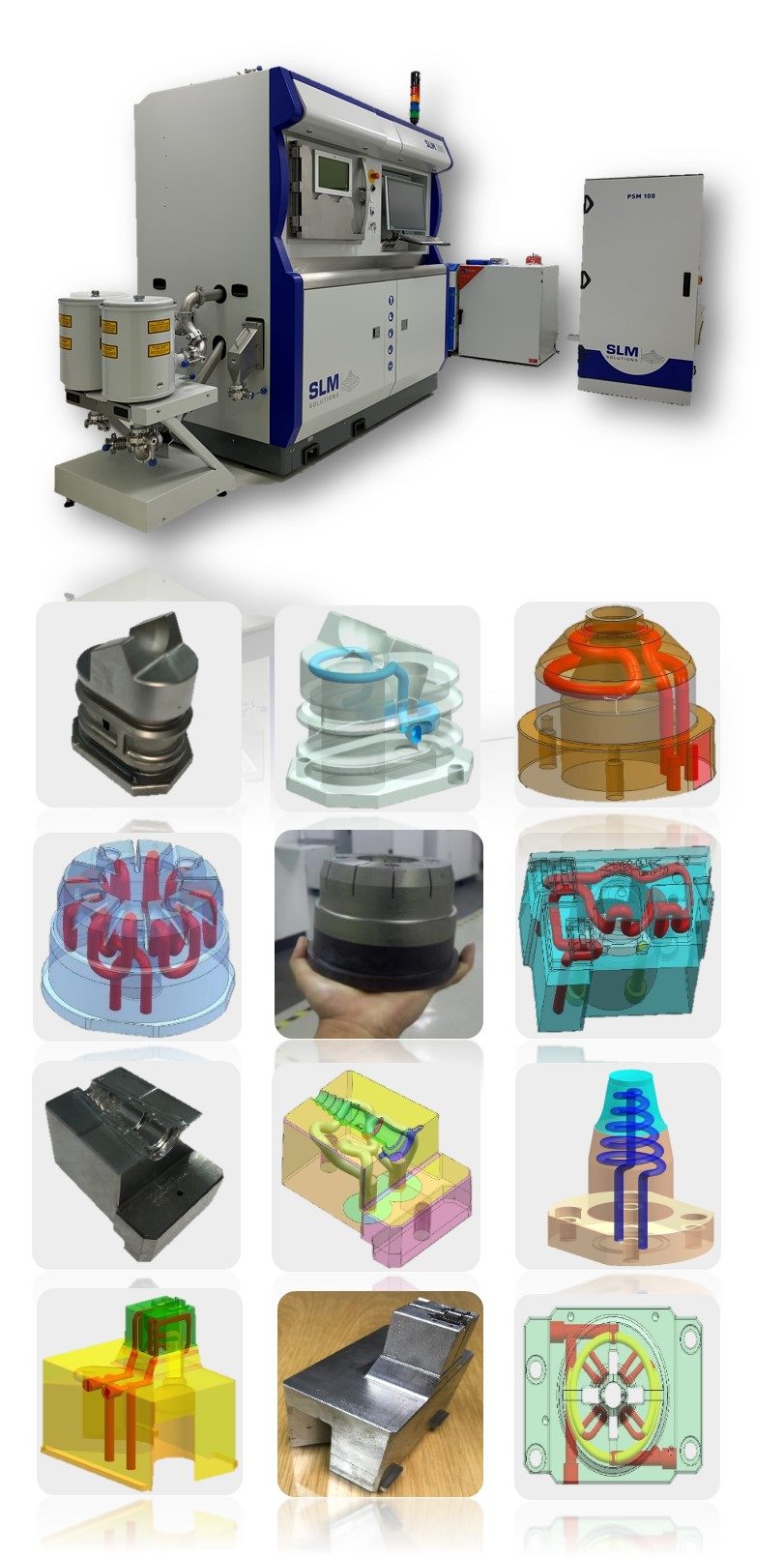

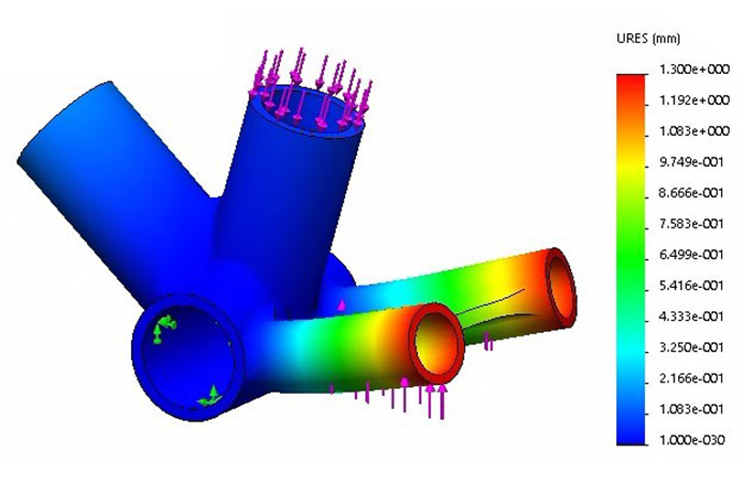

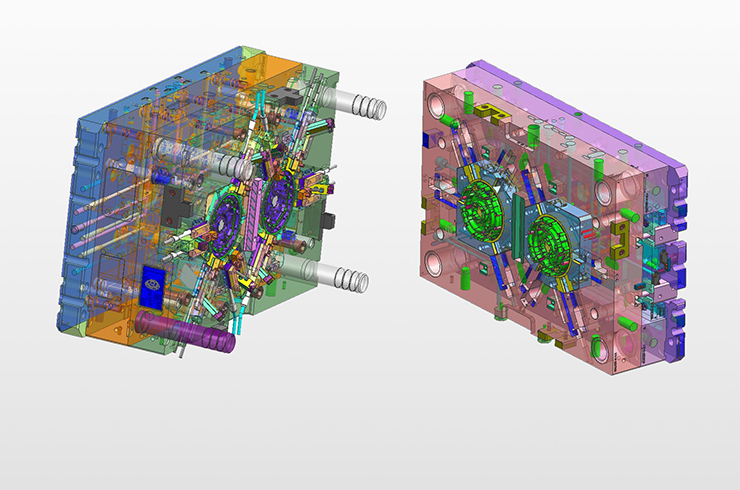

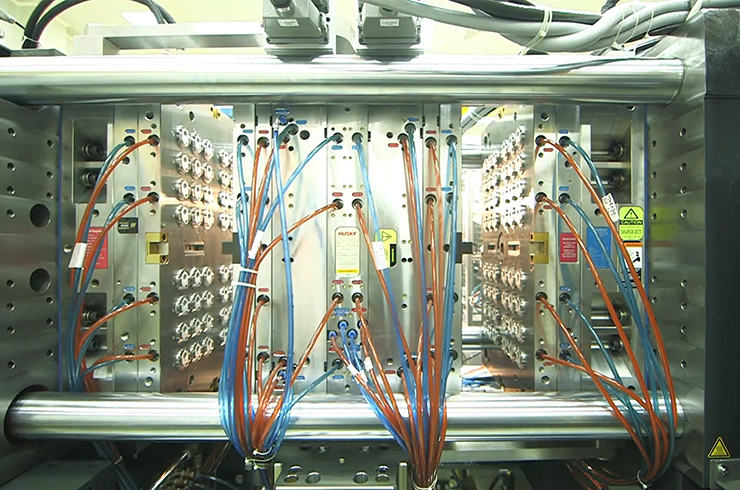

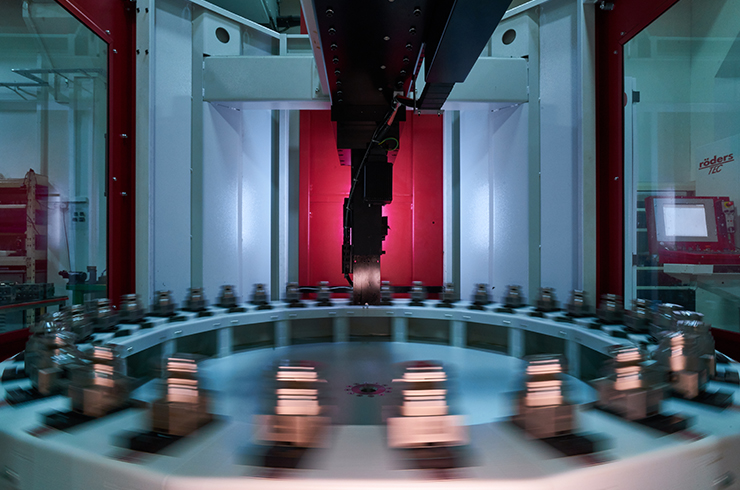

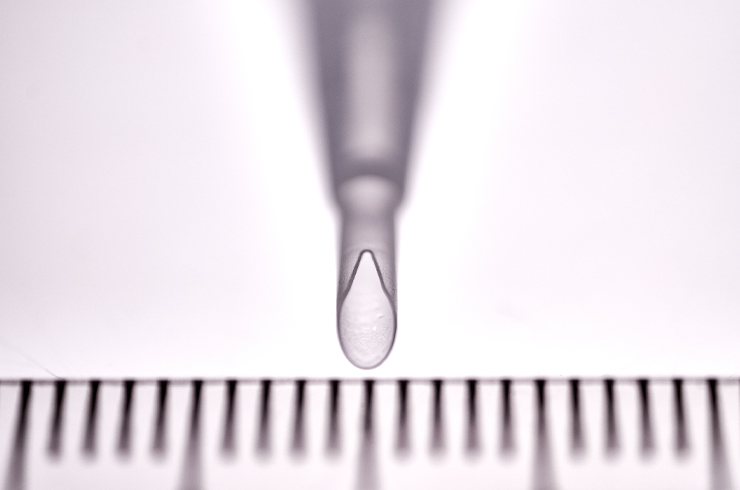

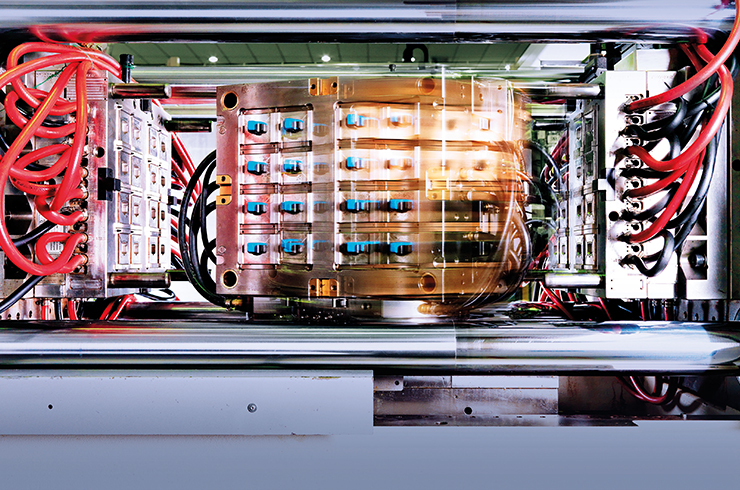

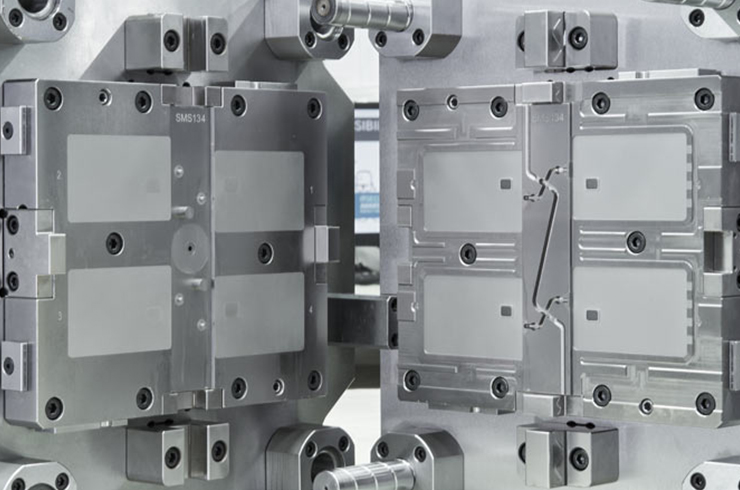

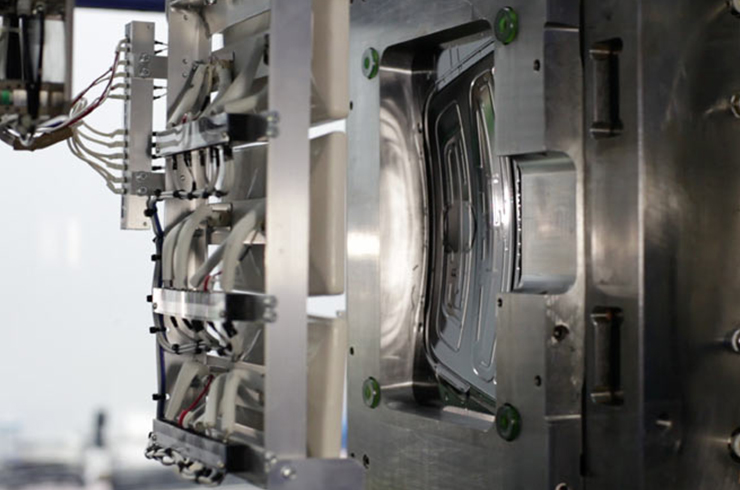

Omni Mold company, is a ultra precision plastic injection mould making company in Singapore. Specializing in ultra-precision, high complex and high cavitation moulds. Our state-of-the-art facility is equipped with advanced computer software and machine tool hardware. Together with proven track records, system and highly trained staffs, we are positioned to meet the requirements of the most stringent customers in the global arena, in sectors such as Medical, Pharmaceutical, Healthcare, Nutrition / Food Packaging, Information Technology, Office Automation, Automotive and Consumer Electronics.